I only had 3 made, one of which is in this picture. I’m going to redesign it at a later point to be far more space-efficient, and I want to transition to SOIC instead of DIP.

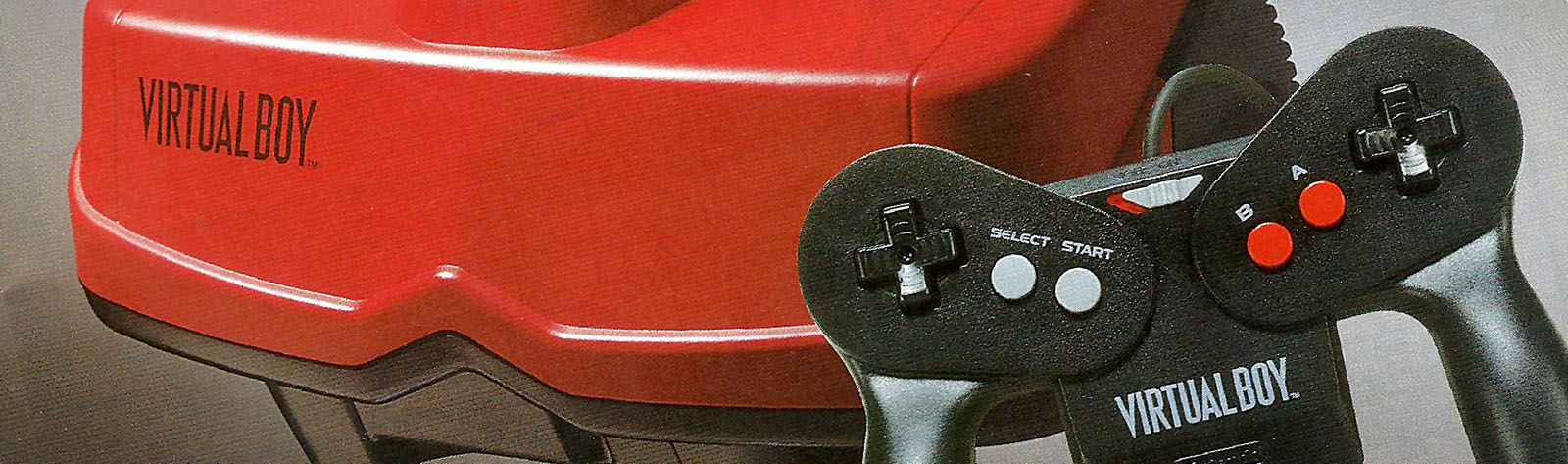

This is the prototype of my solution. Seems to work pretty well.

Attachments:

Yes ; however, bear in mind that 0.6mm pitch is decidedly not industry standard, and the 0.8mm motherboard connection makes an off the shelf flex cable impossible.

Hahaha hahaha!

See my VirtualCable and VirtualSolution threads…

On the motherboard side, the VB uses a standard pitch cable connector. It’s the LED board that uses a non standard pitch. In addition, the six outermost “pins” on the LED board side are NC, for reasons that nobody has been able to provide a good explanation for. Only 30 pins actually have any purpose on the cable at all.

Travel back to 1996 and buy one brand new. There is no current method of fixing the displays without soldering. Baking comes closest but is iffy. There is a 3D printed bracket that you can install to apply pressure to the pads, but it’s not a guaranteed fix.

VB Boy wrote:

I’m interested in these since one of my eyes is giving me trouble here and there and I haven’t worked up the nerve to dive into solder fixing mine yet.My main question is with this part how would one remove the glued portion of the old ribbon to give a clean surface to solder this part to.

Also I was reading and I was curious would this require more or less the same soldering skills that are required to do a normal solder fix. Or would the castellated holes make this job a piece of cake for people with amateur soldering skills.

Looking forward to see your progress on this part. I am very interested!

-Cameron

Since the original cable is not soldered down, a bit of heat, like from a soldering iron, will tear right through that glue. I suppose you could also use IPA, which would take a bit longer but be less aggressive.

The castellated holes here, because they are on a PCB and have plenty of mass, would allow for a solid bond to form very easily. Flux is, of course, your friend, but it will be much simpler than either the original fix method or the VirtualCable. An amateur could manage it, but it wouldn’t hurt to have a modicum of experience before trying.

Edge Connector wrote:

I’d be interested in four of these cables. I’m sorry I missed your messages about the previous solution my preferences weren’t set right to forward PMs to my email.Let me know how I can order and I’ll send you payment right away this time!

I’m in the process of testing this method, as I’d rather not get embarrassed like I did with the VirtualCable. It may be a bit before I determine that these are good for sale.

Alterac wrote:

Looks like a great solution.Which PCB Fab was able to make castellated holes that close together?

My usual fabs (JLPCB, PCBWay, Osh, etc) dont let me have less than 0.6mm.

OSHpark made the prototype boards, and they did require a bit of cleanup. My production fab house for this is actually PCBWay, and they do require some tweaking, but it is doable.

Nes Freak wrote:

i was right!btw this look like it will be about the same difficulty as just soldering an existing cable. put be down for a few pairs

In fact, it should be even easier, as the PCB board won’t detach and fry itself under the heat of your soldering iron.

Just received the prototypes for my ‘unconventional solution’. No spoilers, but initial testing looks good. Some minor issues were observed, and some alterations were made accordingly. Revised prototype for this alternate avenue is out to the fab house again; I hope to introduce more mechanical stability. This ‘unconventional’ solution is looking so promising that I may actually scrap the 2.0 VirtualCable if I can make the numbers work. Stay tuned!

You’ll need to update the Retrode firmware to the latest version to read some games. Hyper Fighting and Red Alarm are two well known problem carts. I think the latest firmware is 0.26b or something. It’s been awhile since I dragged my Retrode out, so I may be wrong there.

Nes Freak wrote:

so you went wit hthe face down methodnice looking foward to trying these out

will the solder be pre on the pads? if so make sure its leaded and tin 60 40 sodler not lead free sodler. lead free solder can grow tin wiskers

The fab house I use does not offer pre-tinning options on flex cables, and the next cheapest fab house that does requires a $2000 setup and tooling fee. That sort of cost for something that only saves the user 20 seconds isn’t a good tradeoff for me.

I’ve sent this design out for prototyping. The fab house I use for prototypes takes a lot longer to produce small runs, so I don’t know when I’ll get it.

-

This reply was modified 5 years, 9 months ago by

RetroDan.

RetroDan.

This is the more ‘conventional’ solution of addressing the issues with my v1.7 VirtualCables. I’m keeping my really exciting solution under wraps until and unless I get all my materials and test pieces in and guarantee an easy, solid solution.

Changes from v1.7:

– Change from a Type B cable (connective ends on opposing layers) to Type A (connective ends on same layers). This means the end of the ‘normal’ installation method of pulling solder up and over pins, and the official adoption of the ‘revised’ installation method, whereby the user applies the soldering iron to the back side of the cable in order to heat the pads, thereby melting the solder and creating an incredibly strong mechanical/electrical connection.

– Removal of castellated holes from 0.6mm-pitch side. They have been replaced by normal holes, intended for orientation rather than connection. There simply wasn’t enough metal mass on the cable ends to form a good connection with castellations.

– Addition of pads for unconnected pads on board. I determined it was too easy for a user to simply miscount or slip while soldering, so the additional 6 dummy pads have been re-introduced in order to eliminate potential installation pitfalls.

– Introduction of test point vias. With the adaptation of the revised installation method, users need an easy way to make sure that their connections are good. Thus, each signal is given an individual, un-tented via (including both GND signals, though this is more for symmetry rather than effect) so that users may quickly and efficiently test each soldered connection one-by-one.

– Elongation of the Motherboard-Side Stiffener. The v1.7 Stiffener was determined to be useable, but too short for comfort or ease-of-use. Therefore, the length of the stiffener has been tripled, which should allow for a comfortable ZIF experience.

– Castellated cutouts for stability. On the LED board, the outermost pads branch out into geometric designs. Utterly useless for its intended function, but by introducing unconnected castellated cutouts, users will be able to orient the cable and use those stylistic pads to tack the cable in place without the possibility of damaging anything by having to remove and resolder a poorly oriented cable.

-

This reply was modified 5 years, 9 months ago by

RetroDan.

RetroDan.

Attachments:

EDIT: I have devised a new installation method that is many, many times easier and 100% reliable, using the current (somewhat flawed) VirtualCables! Please check the first post of this thread.

At the Post Office right now, halfway through. Filling out customs declarations en masse is not fun. I’ll send each buyer a copy of their customs receipt when I get home.

Phew.

It appears that I have 14 pairs of cables available from buyers who did not pay. I’m holding on to four of them, but the other ten are first come first serve. I’m going to try a new installation method for the current cables that might be easier and more importantly, create a stronger bond. I’ll update the thread as I figure things out.

-

This reply was modified 5 years, 9 months ago by

RetroDan.

RetroDan.

Gah.

So I just get over the most terrifying illness of my life, and guess who gets called in to work during shutdown?

Me.

Not to worry. I’m at work now, but today is the last day of work I’m needed for. I’m hitting the post office in the morning and shipping out all the remaining cables.

Thank you all for your patience and understanding.

I also have prototypes coming for a completely redesigned solution that, if it works, will be scads easier to install, as well as…well, I’m not giving everything away just yet, but I guarantee that if it works, you will go absolutely bananas over.

On medication now. Still a bit fuzzy. All next week my business is closed for holiday, so I’ll be using that time to ship the last cable orders out.

Some users never responded, so I have some extra cables. Will update later.

I’m not going to the Post Office today. Let me explain.

Something is going on with me – I don’t know what – but I’m suffering from pretty bad vertigo for the first time in my life, which is terrifying for someone who’s always been pretty healthy and who is very independent. My doctor says that it’s not uncommon for fluid buildup to mess with the inner ear.

But I’m not safe to drive. I took a five mile round trip to pick up some things from my mom’s house, and it was excruciating and extremely difficult. Maintaining balance is very difficult. My fiancee has offered to take care of the international packages for me on Monday, and I sincerely apologize for this further delay.

I’m honestly kind of scared. I’ve NEVER been sick like this. It makes me feel weak and dependent, and I don’t feel in control of myself. Even sitting in front of my computer, I’m dizzy and nauseated.

For my international buyers:

Sorry for the delay. I’m dealing with a recurring illness, though I have every intention of getting to the post office this Saturday. Last week, I got my ass kicked by the flu, or food poisoning, or SOMETHING that was the world’s most effective (if unpleasant) weight-loss plan. Then my fiancee caught bronchitis, and in a loving gesture, gifted me with a cold that has poleaxed me.

It has been a rather rotten couple of weeks, to be sure.

Rest assured, I haven’t forgotten about you lads, I’ve just had almost no energy and a cough that makes smokers blue with asphyixiatic envy.

Keep the faith, lads.